What Is Electronic Potting Material

What Is Electronic Potting Material

Potting electronics is a way to fill up an entire electronic hardware setup with a strong material that gives it protection against corrosion, vibration and moisture. It’s almost like giving your electronics an extra layer of armor so they can survive extreme conditions!

Gone are the days where mechanical components used to be exposed to increased levels of wear and tear, leading to material fatigue. But with this relatively newfound reliance on gadgets almost exclusively made up of solid-state technology, one is bound to run into a handful of issues that could potentially stop it from functioning properly.

Moisture in electronics has the potential to cause a lot of problems – triggering false alarms, ruining functioning, and corroding components and systems overall. Encasing vulnerable parts is often a work-around way to keep them safe from corrosive agents – but this can become bulky, expensive and weigh down the design. So, when it comes to handling moisture issues we’re stuck between a rock and hard place!

Caring for fragile electronics is sometimes easier said than done. That’s why potting them up is the way to go! Potting means that vulnerable components can be safely enveloped with compounds that serve as protective layers sealing them from factors such as shock and vibration or moist corrosion. All together this method of encapsulation ensures valuable electronics will remain untampered and strong – just what they need!

The Electronic Potting Concept

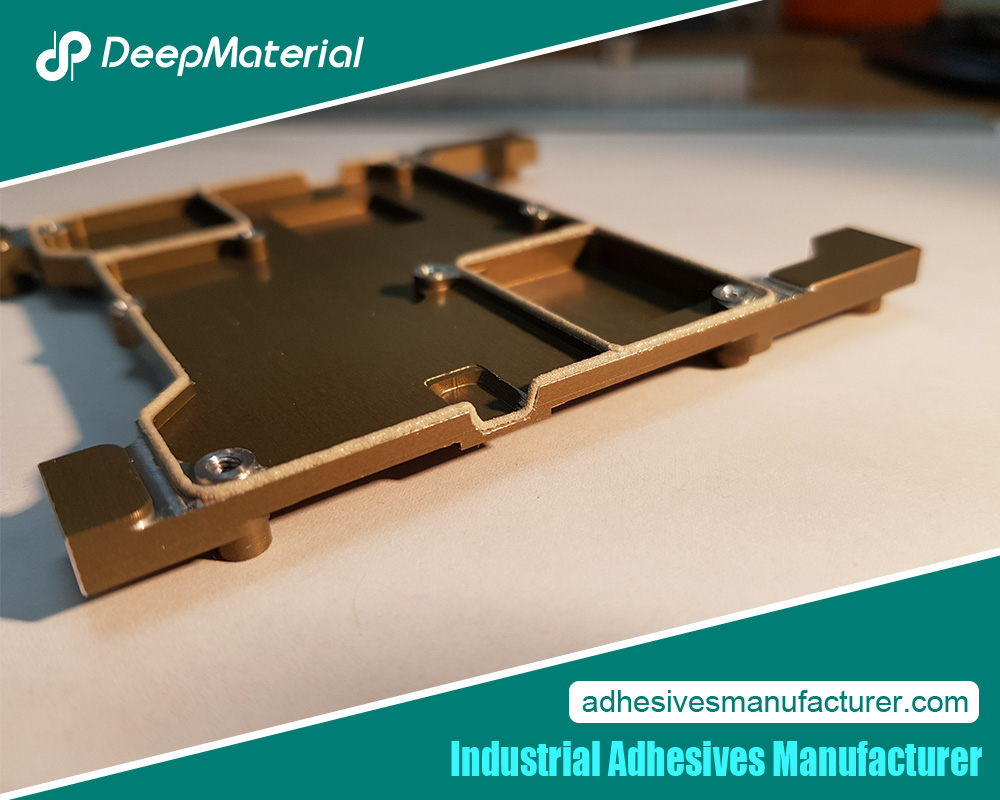

Let’s take a peek at how electronics “potting” works. Basically, you create the perfect fit for your electronic pieces to live in, then it’s just a matter of adding those special temperature-controlled and adhesive liquids like epoxy and polyurethane or silicones into the ‘pot’.

Bear in mind that sometimes these mixtures are poured into molds instead and removed after they harden; other times, components can just be slathered with the compound for coverage.

Potting electronics has tons of perks – it’s incredibly versatile. Not only can you pot high-risk pieces and entire boards, but there is an array of materials that handle conductivity needs, electricity insulations, heat insulation while still protecting against environmental problems. It all adds up to quite the package!

What Electronic Potting Looks Like

So, what’s the deal with potting? That all depends on what and how you’re using your materials.

Having issues with potting materials? Well, you have to watch out for those reacting with certain adhesives or components – if that happens, it could leave some areas uncured. Your best bet is identifying the correct compound right off the bat; missing your target there can mean some electrical parts won’t be adequately sealed. That’s why you’ve got to make sure these are spotted before any unwanted potting material winds up in the wrong places and compromises any chance of a successful operation down the line.

Every potting compound needs its own kind of treatment. From mixing techniques to temperature adjustments to getting rid of all those pesky bubbles, it’s a whole tedious process. If the project in question is particularly challenging, then you may be better off using higher viscosity materials or heat them up at a higher temperature. It’s always different for each one.

Equipment for Electronic Potting

The electronic potting process is no piece of cake, needing seriously specialized equipment to get the job done. You’re looking at machines that precisely and evenly mix the material you’ll be potting with, plus tanks that take out all those pesky air bubbles.

And if it’s not precise enough for you, these setups are calibrated to give you control over the ratio and flow speed of your materials too!

In terms of other necessary tools, there’ s going be vacuum chambers with adjustable temperatures as well; adjust them accordingly depending on how long a curing period you’re setting up – something which can affect shrinkage down the line.

Quality & Process Inspections

The first time, the techs look carefully to see how the potting fills up and gets hard. Then, they cut tiny pieces to check really closely – looking at each piece with a microscope to find anything strange.

Once they’re sure everything looks good, they write down all their notes and observations. But if something is wrong, they fix the recipes or ingredients until everything is just right—keeping some potting samples in place to make sure the amounts are correct!

Electronic Potting Benefits

The payoffs of potting are sizable. Not only does it shield against moisture and the elements, but also jarring and vibrations. It takes away any pesky danger from air and moisture so nothing stands in the way of upkeep, dependability, or durability – all while guarding critical noise-prone parts and components sensitive to electromagnetic waves.

Comparing Potting to Other Solutions

Potting can be a smart, money-saving way to protect electronics. But there are other ways too – like using conformal coatings and enclosing components with fully sealed housing. Both have their benefits but they may not always be the most cost-effective solution, unlike potting! Plus, neither of these alternatives address trapped hot air, which is where potting really shines, making it often the most sensible choice when it comes to affordability and robustness.

Some Electronic Potting Applications

- The Automotive Industry – The automotive industry isn’t what it used to be – it relies heavily on an increasing range of electronics parts and systems that can all be subject to dirt, liquids, moisture, vibration, and extreme temps. Potting those important parts and components is crucial for upping reliability so your car doesn’t turn into a lemon before you know it.

- Construction – At the end of every construction shift, forklifts and other heavy-duty vehicles have to get a good splashing with the pressure washer. So, it’s essential that their electronic systems and pathways be reliable enough for them to keep running without any troubles. And potting shields those more delicate parts from potential harm.

- Infrastructure Electronics – Crumpled traffic lights, rickety switches, worn-out power supplies and overstressed sensors require sealed enclosures for safe operation. But given the era of aging, thermal stress and UV rays which slowly corrode enclosures’ effectiveness, smooth functioning can no longer be taken for granted. A genius strategy like component potting could help bring reliability back on board as well as minimize repair and replacement costs. Afterall who’d want to incur unnecessary expenditure when a solution’s already at hand?!

Aside from the few aforementioned cases, there are tons of electronics out there with the potential to come in contact with water or extreme temperatures. Even if it’s just a small crack, this puts them at major risk since any hint of moisture can trigger serious corrosion damage. That’s where electronic potting comes in – it offers the much-needed shield!

Final Thoughts

Electronic potting serves as a vital shield for devices, protecting against environmental threats and enhancing their resilience. This encapsulation method, with its customizable materials, ensures long-term reliability in diverse applications. Electronic potting secures components, promotes durability, and contributes to the sustained performance of electronic systems in challenging conditions.

For more about a complete guide to Electronic Potting Material, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.