DeepMaterial Industrial Adhesive Pruducts

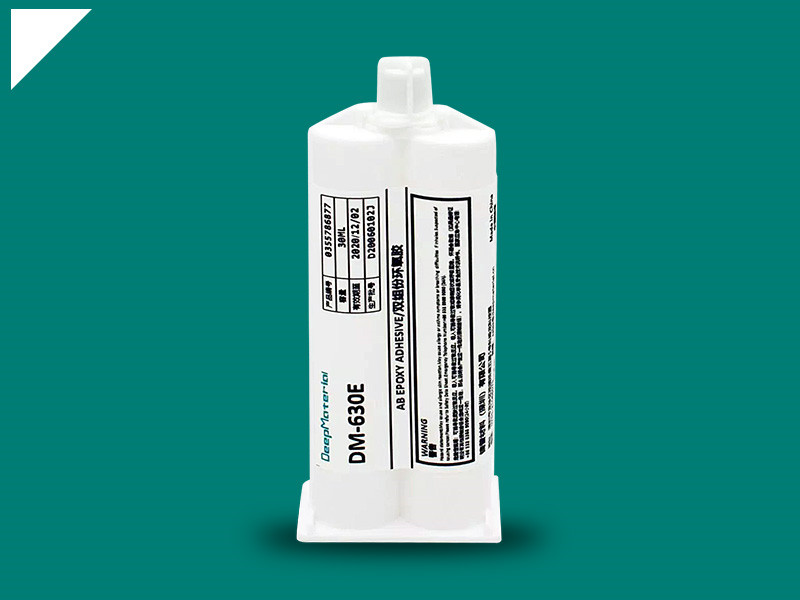

Deepmaterial is a the manufacturer of epoxy adhesives including hardeners, metalbond, and metal filled resins. Structural, toughened medium viscosity, and non-sag adhesives are also offered. Some adhesives are resistant to thermal shock, chemical, vibration dampening, and impact. Suitable for metals, plastics, wood, and ceramics. Serves electronics, aerospace, automotive, tooling, marine, and construction industries. REACH and RoHS compliant. FDA approved. UL listed. Meets military specifications. We are the one of best adhesive manufacturers in China.

DeepMaterial has developed industrial adhesives for chip packaging and testing, circuit board-level adhe- sives, and adhesives for electronic products. Based on adhesives, it has developed protective films, semiconductor fillers, and packaging materials for semiconductor wafer processing and chip packaging and testing.

To provide electronic adhesives and thin-film electronic application materials products and solutions for communication terminal companies, consumer electronics companies, semiconductor packaging and testing companies, and communication equipment manufacturers,to solve the above-mentioned customers in process protection, product high-precision bonding, and electrical performance.

DeepMaterial offer different kinds of products about industrial adhesive for electric, UV curing UV adhesive series, reactive type of hot melt adhesive and pressure sensitive hot melt adhesiveseries, epoxy-based chip underfill and COB encapsulation materials series, circuit board protection potting and conformal coating adhesive series, epoxy based conductive silver adhesive series, structural bonding adhesive series, functional protective film series, semiconductor protective film series.