The scientifically proven glue for magnets in electric motors

The scientifically proven glue for magnets in electric motors

Industrial adhesives are central when it comes to making important products like electric motors. Before this product is made, it requires the use of a high-performance bonding solution called adhesives. These industrial adhesives are usually manufactured to withstand extreme environments. They are also made in such a way that they make the final product durable, strong, and light. One important industrial adhesive is glue for magnets in electric motors. Electric motors are critical mechanical components that are made of various dissimilar materials. To create cohesive and durable products, scientifically proven glue for magnets is used.

What are electric motors used for?

What are electric motors used for?

Electric motors are instruments that are used to convert energy in the form of electricity to motion. This device is supplied with energy to get it to generate rotational motion. Electric motors are instruments that can be used to produce a drive output. They can be made to be very big or small.

Electric motors in our everyday lives

By the working principle of the electric motor, many of our home and work appliances can work effectively. The electric motor is a crucial mechanical equipment that is used in electric toothbrushes, home pumps, and so on. Because they produce rotational motion from electrical energy, these mechanical devices are everywhere. Every year, over 2 billion electric motors are used in the automotive industry alone. However, one fact about electric motors is that you cannot make them without using adhesives. Electrical motors are very superior to other mechanical options because they provide a premium combination of benefits. This is why there are many industrial electric motor adhesive manufacturers.

Using industrial adhesives for bonding magnets

Magnets are special materials that are utilized in the creation of other products. Magnets require the use of the best industrial adhesives to achieve key objectives in the manufacturing industry. When boding magnets, adhesives can be used with some other materials such as:

- Metals:Magnets are used with metals to produce electric motors. The best glue for magnets in electric motors usually works for several metals such as copper, aluminium, brass, and steel. These metals can be bonded seamlessly with magnets to create products like the electric motor. Industries like construction, aerospace, and automotive rely on bonding magnets and metals to form special products.

- Plastics:Magnets can be used as a material for bonding to plastics. Due to the versatility of industrial adhesives, they can be used as bonding agents for magnet-to-plastic joints. Many industries rely on the efficacy and performance of adhesives to produce various magnetic/plastic products.

- Wood:Magnets can be bonded seamlessly to wood to create an innovative product. Due to this characteristic, they are highly indispensable and useful.

How glues for magnets in electric motors are used

Electric motors are very delicate machine components that are meant to produce a certain performance. If this part of the machine is not produced properly, it will affect the long-term working function of the equipment. Glues for magnets in electric motors are used depending on the requirements of the working condition. Some available for this operation include acrylics, epoxies, and many more. Apart from glues, it is also important to use the right curing methods. When it comes to gluing magnets in electric motors there are usually different curing methods that are used. These are:

- Ultraviolet curing

- Ozone curing

- Thermal curing

Best glue for magnets in electric motors: Stages involved when applying adhesives

When it comes to the application of adhesives for bonding magnets in electric motors, there are three crucial steps involved. These steps include:

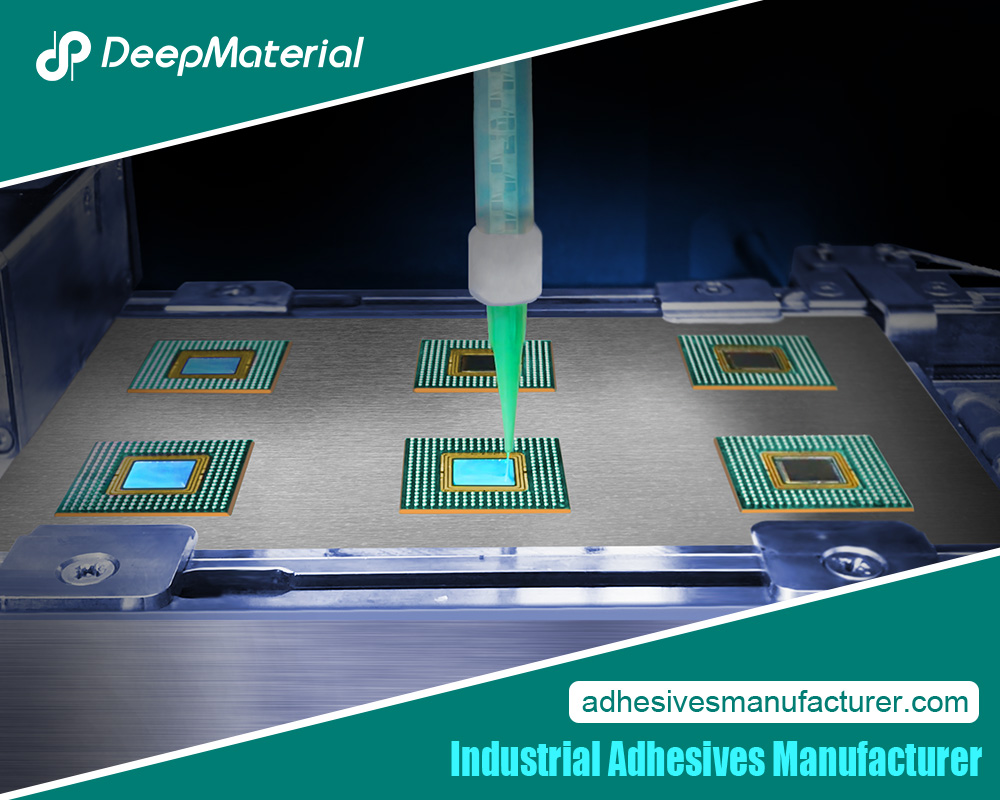

1). Injecting the adhesive: The adhesive is injected between the magnet and the metallic substrates in the electric motor. It is important to note that the glue is dispensed with an automated or an operated dispenser.

2). Curing the adhesive: Once injected into the electric motor, the glue is then worked into position. After that, it can easily be cured using heat, UV light, or ozone.

3). Reactivating the adhesive: After the curing process is complete, the adhesive is reactivated to proceed to create a strong bond between both substrates in the electric motor.

Why curing is important with glues for magnets in electric motors

Electric motors are made from the combination of magnets with other metallic materials. When fully produced, the electric motor is expected to produce rotational motion. Since this product will be expected to vibrate for the majority of its working life, it is expected to be produced by highly engineered adhesives. This is why the best glue for magnets is used to bond its components together. After all the parts of the electric motor are bonded together, they are then cured. Curing helps activate all the innate properties of the adhesive. Many curing methods are particular to specific glues. Since there are specific adhesives used for bonding components in the electric motor, this product requires a special curing process. For example, the UV curing method is usually used for curing a finished electric motor after the application of the adhesive. The chosen adhesive is used on the electric motor because it can create strong bonds that will last for a long time.

Benefits of the best glue for magnets in electric motors

Benefits of the best glue for magnets in electric motors

When it comes to the best glue for magnets in electric motors, adhesive manufacturers work to produce a wide range according to different requirements. This is why there are no particular adhesives for making electric motors. Generally, manufacturers are expected by best industry practices to produce premium and high-quality adhesives for this purpose. When you choose a reliable manufacturer as your supplier, you get a wide range of benefits. This includes:

- The glue for magnets in electric motors supports easier automation of your assembly facility.

- The adhesives are simplified to easily work with different operations and processes

- The adhesives are made to prevent air and fluid leaks.

- They are made to reduce noise and vibration.

- Adhesives for electric motors are made to maintain insulation between laminations in the product.

- The adhesives are made to improve power in the electric motors.

For more about the glue for magnets in electric motors, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.