An expert’s guide on the best glue for magnets to metal

An expert’s guide on the best glue for magnets to metal

In industrial environments, there are several reasons magnets are glued to metals. When both materials are bonded together, they are used to produce a wide range of products. Since magnets are special types of materials that attract metals, it is important to use the right adhesive whenever this type of bonding is being executed. The best glue for magnets to metal for this project is used to ensure durable and high-strength bonds. Adhesives for bonding magnets to metals in various applications are very important. This is because they help to enhance the performance and functionality of the final product. This is why it is important to always use the best adhesives for this process.

Applications of magnets in our everyday lives

Due to the industrial usefulness of magnets, they can be used to produce a wide range of highly efficient products. Before these products are made, there is usually the bonding of magnets to metal. In this case, the manufacturer usually relies on the best glue for magnets to metal products to create the products. Some of the products that can be created this way include magnetic sweepers, speakers, electric generators, electric motors, cranes, and so on. Before these products are made, the manufacturers usually source industrial magnets for metal adhesive makers.

The best glue for attaching magnets to metals

We have seen that some of the most effective industrial products are made by bonding magnets to metals. There is a wide range of adhesives that are suitable for glueing magnets to metals. Many of these adhesives are engineered with special properties. This depends on the working environment for the final product. For instance, the best glue for magnets to metal in a marine application should be able to resist water. This adhesive should also be able to cure very fast. This is why product makers usually need efficient and competent adhesive manufacturers to support their production operations. A reliable adhesive manufacturer can help product makers develop quality products and boost revenue. The best magnets to metal adhesives should be able to hold magnets to metals for a long time. This is important because not every adhesive can realize this result.

Industrial bonding of magnets to metals

When it comes to bonding magnets to metals, there is a wide range of adhesives that are used. One practical example is in attaching coils and motors to vessels using acrylic adhesives. Apart from this obvious example, there are many industrial examples where magnets are attached to metals. Other examples are electromagnets, cranes, medical machines, and so on.

Bonding magnets to metals: Types of curing processes

Apart from using the best glue for magnets to metal bonding, another important part of this process is curing. With the right curing method, you can set up the bond for high strength and increased durability. Also, when you use the wrong process of bonding, it can cause the joint to be damaged at some point. The following curing processes are used to join magnets to metals.

UV curing: After attachment, the adhesives are cured using ultraviolet light. The process of curing adhesives with UV light is delicate and complicated. It requires the use of specific industrial gear and equipment. When UV is used as a curing method, it helps to prevent the motor from wearing and tearing. It protects the electric motors from damage and rust. If the process is applied correctly, it helps to keep the product in the proper condition for a long time.

Ozone curing: Magnets to metal bonding processes are also cured by using Ozone. This type of curing method is used often for curing metallic parts that are bonded with magnets. The ozone curing method is very effective and helps strengthen the bond to increase its durability. With the right equipment, ozone curing is a fairly easy process.

Thermal curing: Thermal curing is another common way of curing magnets to metallic bonding. This is an industrial curing method that relies on heat to cure components that have been bonded together. Thermal curing for magnetic to metallic bonding is highly durable and very effective. It can be applied fairly easily and fast.

The process of bonding magnets to metals in industrial environments

Many industrial products are produced simply by bonding magnets to metals. This is why this process is very delicate and important. When it comes to bonding magnets to metals in industrial environments, three core stages are used. These include:

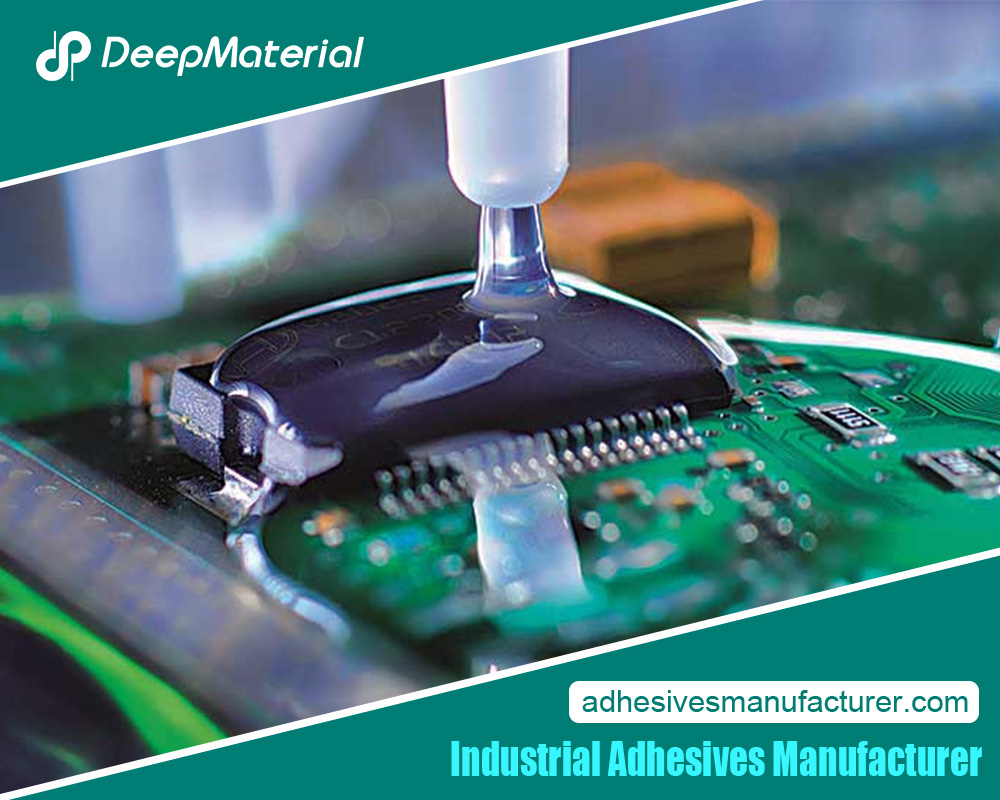

1). Injection: The injection stage involves the process of applying the adhesive to the magnet and metal combination. This process is executed using special injecting equipment. As a delicate process, the adhesive needs to be dispensed adequately to ensure effective workability and high-strength bonding. When injected into the required area, the magnet and metallic materials are then pressed together.

2). Cure: The next stage involves curing which involves exposing the bonded joint to curing agents such as heat, UV light, ozone, and so on.

3) Reactivation: After the curing process is complete, the adhesive applied is usually reactivated to conclude the bonding process.

Using magnets for various industries

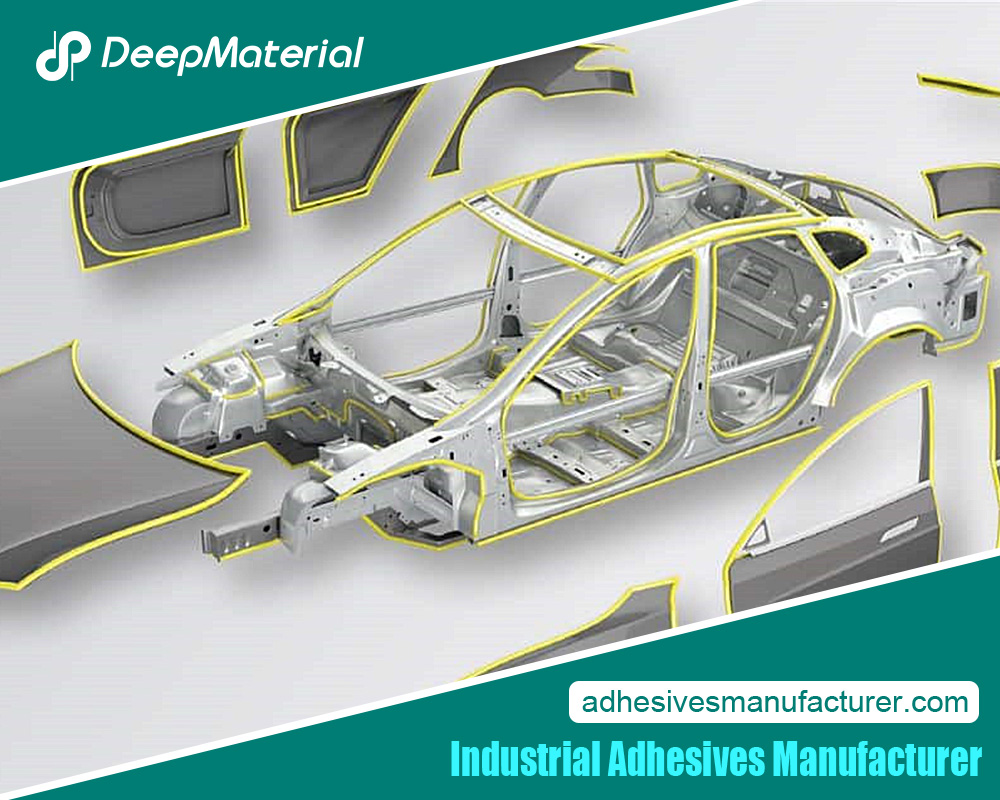

The use of magnets is common in many industries. This is why bonding magnets to metals is a very important process. Magnets to metallic bonding are used to produce several industrial materials for household equipment, electrical machinery, power tools, automotive, audio and video equipment, and so on. Today, there is an abundant production of products that are manufactured after bonding magnets to metals.

Getting the best glues for magnets to metal

The industry for manufacturing adhesives is a wide business sector that continues to expand. This is as many technological robots and autonomous systems continue to find relevance in our everyday lives. Many of these products require the bonding of magnets to metals. Since each of these products is used differently and in varying working conditions, they will need to be assembled using different adhesives. One way to get the best glue for magnets to metal product creation is to get a good supplier with the capacity and expertise to meet your requirements.

For more about the adhesive manufacturer, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.