Strategic Adhesive Expertise: Industrial Adhesive Solutions Manufacturers

Strategic Adhesive Expertise: Industrial Adhesive Solutions Manufacturers

As the backbone of countless products and processes, adhesives play a pivotal role in ensuring the integrity, durability, and functionality of a wide array of items. From automobiles to electronics, furniture to packaging, industrial adhesives are the unsung heroes that hold our world together.

In this blog post, we will analyze Strategic Adhesive Expertise: exploring its significance in industrial manufacturing, examining the role of Industrial Adhesive Solutions Manufacturers, and shedding light on how these specialists contribute to various industries’ growth and advancement.

The Importance of Strategic Adhesive Expertise in Manufacturing

Strategic adhesive expertise is vital in manufacturing as it can significantly improve manufacturing processes. Adhesives are used to bond materials together, and the right adhesive can enhance the strength and durability of the bond. Strategic adhesive expertise involves understanding the specific requirements of each manufacturing process and selecting the most suitable adhesive for the job.

Industries such as automotive and aerospace require adhesives that can withstand extreme temperatures, vibrations, and other harsh conditions. Without strategic adhesive expertise, manufacturers may end up using adhesives that are not suitable for these demanding applications, leading to product failures and costly recalls.

Benefits of Working with a Strategic Adhesive Expert

Working with a strategic adhesive expert can provide several benefits for manufacturers. These experts have in-depth knowledge and experience in adhesive technology and can provide customized adhesive solutions that meet the specific needs of each manufacturing process.

Customized adhesive solutions are tailored to the unique requirements of each manufacturing process. A strategic adhesive expert will assess the materials being bonded, the environmental conditions, and other factors to recommend the most suitable adhesive. This ensures that the bond is strong and durable, leading to improved product quality and reduced waste.

Working with a strategic adhesive expert can also improve efficiency and productivity in manufacturing processes. The expert will have a deep understanding of adhesive application techniques and can provide guidance on the most efficient and effective way to apply the adhesive. This can result in faster production times and reduced downtime.

Additionally, a strategic adhesive expert can help manufacturers reduce waste and downtime. By selecting the right adhesive and providing guidance on application techniques, the expert can minimize adhesive waste and prevent issues such as bond failures or rework. This leads to cost savings and improved overall productivity.

Customized Adhesive Solutions for Specific Manufacturing Needs

A strategic adhesive expert can provide customized adhesive solutions for specific manufacturing needs. These solutions are tailored to meet the unique requirements of each manufacturing process, ensuring optimal performance and durability.

For example, in the automotive industry, adhesives are used for bonding various components such as body panels, glass, and interior trim. A strategic adhesive expert can recommend adhesives that have high strength and durability, as well as resistance to temperature fluctuations and vibrations.

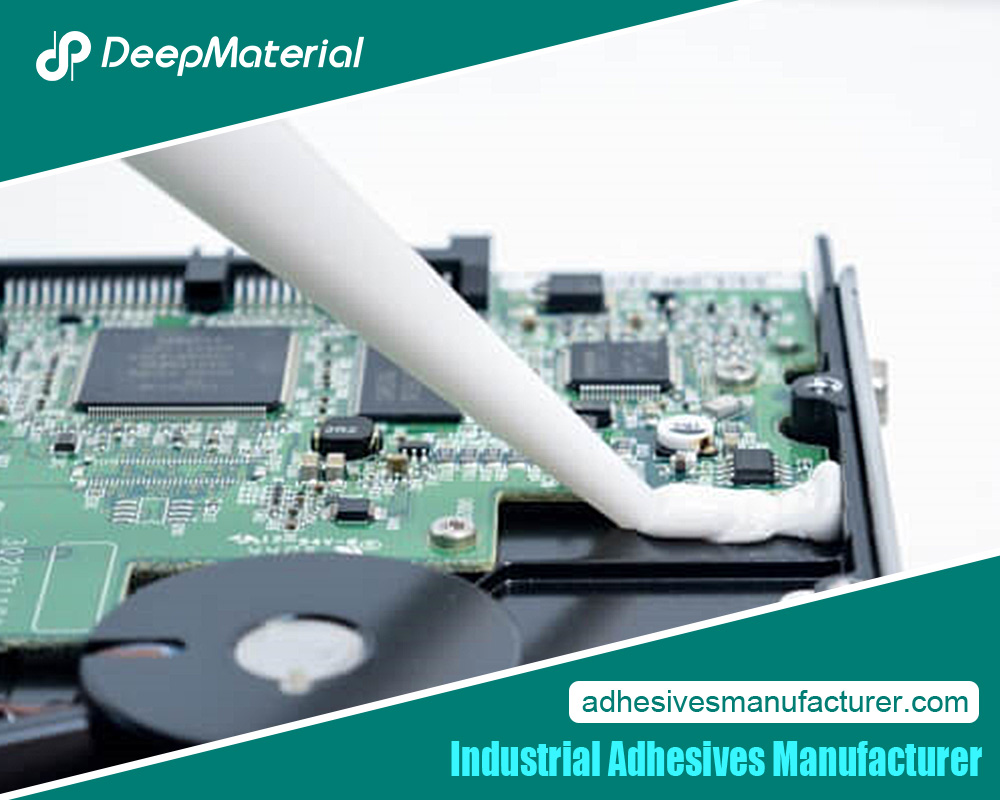

In the electronics industry, adhesives are used for bonding components on circuit boards and for sealing electronic devices. A strategic adhesive expert can recommend adhesives that have excellent electrical conductivity and thermal stability, ensuring reliable performance and protection against moisture and other environmental factors.

Customized adhesive solutions offer several benefits for manufacturers. They ensure that the adhesive selected is the most suitable for the specific application, leading to improved product quality and reduced waste. Customized solutions also take into account factors such as environmental conditions and regulatory requirements, ensuring compliance and sustainability.

Adhesive Testing and Quality Control in Manufacturing

Adhesive testing and quality control are essential in manufacturing to ensure that the adhesive performs as expected and meets the required standards. Adhesive testing involves evaluating the adhesive’s properties, such as strength, flexibility, and curing time, through various tests and measurements.

There are different types of adhesive testing that manufacturers can perform. These include lap shear testing, peel testing, tensile testing, and impact testing, among others. Each test provides valuable information about the adhesive’s performance under different conditions and helps identify any potential issues or weaknesses.

Quality control measures are also important to ensure consistent adhesive performance. This includes monitoring the adhesive manufacturing process to ensure that it meets the required specifications and standards. Quality control measures may include regular inspections, batch testing, and adherence to industry standards and regulations.

By conducting adhesive testing and implementing quality control measures, manufacturers can identify any potential issues or weaknesses in the adhesive early on and take corrective actions. This helps prevent product failures, recalls, and costly rework, ensuring that the final product meets the required quality standards.

Sustainability and Environmental Considerations in Adhesive Manufacturing

Sustainability and environmental considerations are becoming increasingly important in adhesive manufacturing. Manufacturers are under pressure to reduce their environmental impact and develop more sustainable adhesive solutions.

Sustainable adhesive solutions focus on reducing or eliminating harmful chemicals and minimizing waste. This includes using adhesives that are free from volatile organic compounds (VOCs) and other hazardous substances. Manufacturers are also exploring alternative raw materials and manufacturing processes that have a lower environmental impact.

There are several examples of sustainable adhesive solutions in the market. For instance, some manufacturers are developing bio-based adhesives that are derived from renewable resources such as plant-based materials. These adhesives offer similar performance to traditional adhesives while reducing the reliance on fossil fuels.

Another example is the development of water-based adhesives, which have a lower environmental impact compared to solvent-based adhesives. Water-based adhesives do not emit harmful VOCs during the curing process and can be easily cleaned up with water, reducing waste and environmental pollution.

The Future of Industrial Adhesive Solutions and Technology

The future of industrial adhesive solutions and technology looks promising, with ongoing advancements and innovations in the field. Emerging technologies are being developed to improve adhesive performance, enhance manufacturing processes, and address sustainability concerns.

One emerging technology is the development of smart adhesives that can sense and respond to changes in their environment. These adhesives can adapt their properties, such as viscosity or strength, based on external stimuli such as temperature or humidity. This technology has the potential to revolutionize industries such as aerospace and automotive, where adhesives need to withstand extreme conditions.

Another area of development is the use of nanotechnology in adhesive manufacturing. Nano adhesives have unique properties due to their small size, such as improved strength, flexibility, and thermal stability. These adhesives can be used in various industries, including electronics, healthcare, and construction, to enhance product performance and durability.

Sustainability is also a key focus for future adhesive solutions. Manufacturers are exploring alternative raw materials, such as bio-based and recycled materials, to reduce the environmental impact of adhesives. Additionally, advancements in manufacturing processes, such as 3D printing, are being utilized to reduce waste and improve efficiency in adhesive production.

Final Words

Strategic adhesive expertise plays a crucial role in manufacturing processes. The right adhesive can improve efficiency, productivity, and product quality, leading to cost savings and improved customer satisfaction. When choosing an industrial adhesive solution, manufacturers need to consider factors such as adhesive types, compatibility with materials, environmental considerations, and cost-effectiveness.

For more about a complete guide to Industrial Adhesive Solutions Manufacturers, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.