Key features of electronic potting compound

Key features of electronic potting compound

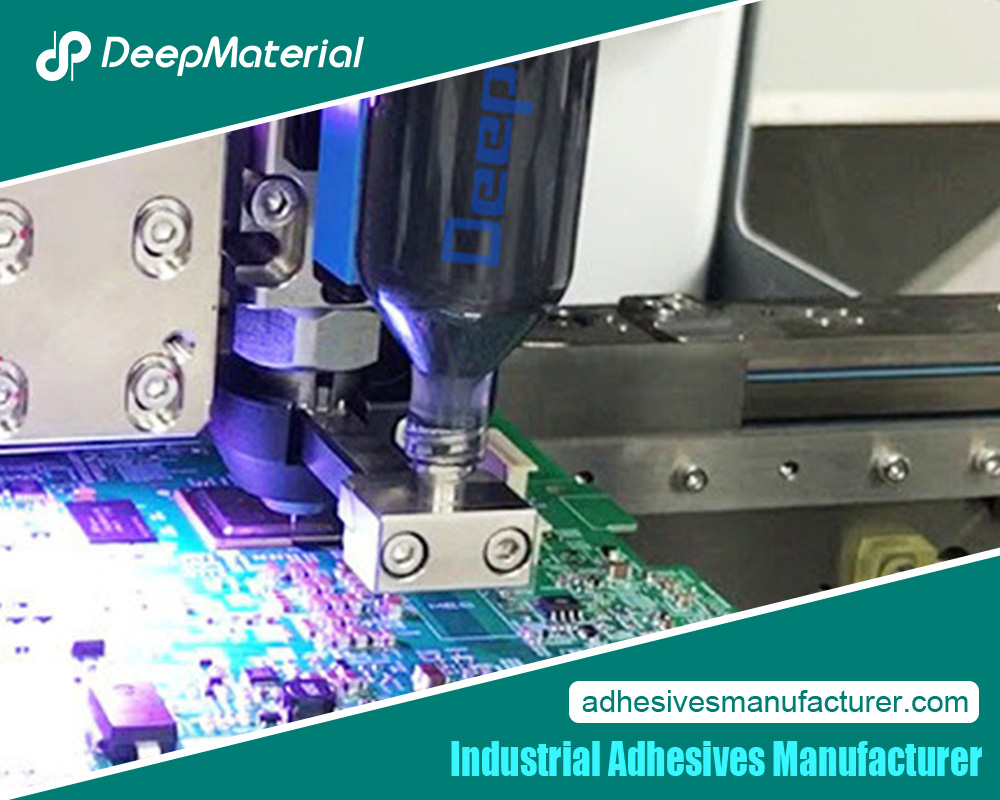

Electronic potting compound works to seal and fill cavities or gaps in electronic assemblies and manufacturing. Electronics manufacturing and assembly face exposure to harsh environmental factors for which it need protection and a safeguarding compound. Electronic potting compound serves to offer this needed protection that is of vital importance. They work as a safeguarding solution against harmful environmental effects. It can offer protection against moisture, vibration, dust, shock, and thermal variations. These compounds also offer protection against other kinds of contaminants that can otherwise result in corrosion and even electric failure.

In addition to protection from external harmful elements, these compounds also offer electric insulation and mechanical strength. Potting compounds are available in a range of products that can satisfy the varying needs electronic devices and the environment where these electronic devices are operated. You must be intrigued to know more about the features of electronic potting compounds. In this article, you will find out all the features of potting compounds that will highlight their types, properties, importance, and applications in different industries. But before we move on to the features, let us take a look at the importance and types of potting compounds.

Importance: Electronic potting compounds are important for offering protection to electronic devices. They play an essential role in protecting the devices against chemical exposure, thermal shocks, vibrations, moisture ingress, and mechanical stress. This compound encapsulates the sensitive circuits, electronic components, and wires to safeguard them against electrical short circuits and corrosion. Their importance is not only limited to protection but it also helps to enhance functional performance. In addition, these compounds also offer support against vibration damping, structural enhancement, and thermal management. It improves the performance, reliability, and durability of electronic devices. In short electronic potting compound is the safeguard against harsh environmental factors and delicate electronic devices.

Types of electronic potting compounds: Potting compounds are available in various types and formulations to cater to different applications, performance, and processing requirements. Here are some common types of potting compounds:

Epoxy Resins: Epoxy resins made with resins and hardening compounds are known for their chemical resistance, strong adhesion, and adhesive capability to bond with various substrates. They are considered as best potting compound for protecting sensitive electronic equipment and devices against harsh environmental factors. They are deemed best suited for the aerospace and automotive industries.

Silicone rubbers: Silicone potting compounds are considered great for qualities such as weather resistance, electric insulation, and adhesion during thermal variation. They are widely used when the temperature reaches an extreme level, to encapsulate sensitive device sensors and in electronic modules.

Polyurethane compounds: These compounds are known for their impact resistance, moisture resistance, and exceptional flexibility. They are widely used to protect devices against vibration damping and thermal variations. They are mostly used in LED lighting equipment and outdoor electronics.

Acrylic resins: these potting resins are known for their adhesion strength, UV resistance, and quick curing. These compounds are best suited for electronic assemblies which require quick processing and are usually placed outdoors.

Key Features: Now that you are aware of the importance and types of electronic potting compounds, it is time to unveil their key features in detail.

Chemical Resistance: Electronic potting compounds show exceptional chemical resistance properties. When exposed to various chemicals, they do not surrender and maintain their sealing properties. These compounds are usually resistant to various chemicals including fuels, solvents, and acids. They offer long-term sealing reliability even when exposed to harsh environments.

Stability in thermal variations: thermal variation is quite normal in electronic devices especially those that are placed outdoors. The potting compound must remain intact even when subject to high-temperature fluctuations. Luckily, the electronic potting compounds are strong enough to withstand huge temperature variations. Even when exposed to thermal fluctuations, these compounds maintain their performance without degrading or cracking. For this reason, they are widely used in aerospace, automotive, and other industrial applications that are installed outdoors.

Mechanical Strength: Mechanical shocks are also common in electronic devices due to various reasons. When potting compounds are used, they offer the needed mechanical support to the delicate components of electronic devices. They save the devices from vibrations, mechanical shocks, and any other probable physical impact that can occur during electronic handling and functions.

Electronic insulation: You must have heard the incidents of electric shocks, short circuits, and leakages in electronic devices. You can protect your electronic devices against all these effects by using electronic potting compounds. They protect your device against all these probable issues and also maintain the integrity of electronic components and circuits.

Water Resistance: Water ingress can cause corrosion, and condensation, degrade the performance of electronic circuits, and can even lead to electronic failure. Potting compounds are water-resistant and can protect your electronic devices against all these possible adverse impacts. By applying the potting compounds you can be sure of the reliability and performance of your electronic device without worrying about the impact of moisture. These features make them perfectly suitable for marine industry and outdoor applications.

Curing abilities: To ensure efficient curing, the potting compounds are formulated in a way that they cure easily. You can use potting compounds with quick cure times but you need ambient temperature for that. Or else, you can use heat to use controlled curing. The efficient curing helps to lead the sealing process efficiently and facilitate assembly operations.

Adhesive properties: Potting compounds have great adhesive properties. The best feature of these compounds is that they can be bonded with various substrates such as ceramics, plastics, and metals. They securely encapsulate the substrate and protect it against any separation as it sticks/adheres strongly to the surface. So, you won’t have to worry about any sort of delamination.

Environmentally compatible: Most of the potting compounds are formulated by keeping in mind the industry standards and environmental regulations. Every manufacturer is going towards sustainable practices to ensure that the potting compounds are environmentally compatible.

High vacuum applications: The potting compounds exhibit great properties for low outgassing. This is why they are considered ideal for high vaccum and space applications.

For more about a complete guide to the key features of electronic potting compound, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.