Shipping your products from an Acrylic Adhesive Manufacturer just got easier

Shipping your products from an Acrylic Adhesive Manufacturer just got easier

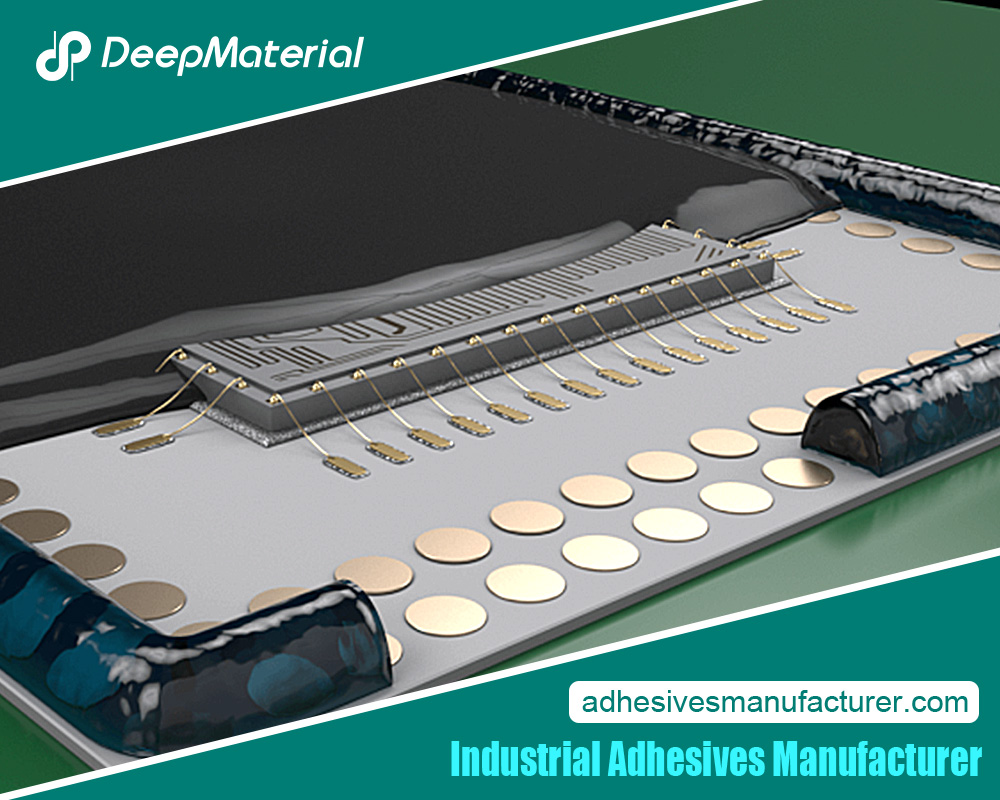

Acrylic adhesives are special chemicals that need extra care and attention when being shipped. They are non-toxic but need special handling and care to ensure that the products are all delivered intact. Acrylic adhesive solutions are usually used in a wide range of industries like signage, construction, electronics, aerospace, and the automotive industry.

What is an acrylic adhesive?

Acrylic adhesive manufacturers usually produce industrial acrylic adhesive solutions for a wide range of applications. These are special adhesives that are produced from acrylic polymers. Acrylic adhesives are used across a wide range of industries and business verticals because of their versatility. Acrylic adhesives are recognized in the industry because they can easily bond to various surfaces such as metals, glass, plastics, composites, and many more.

What are acrylic adhesives made from?

Acrylic adhesives are industrial bonding solutions that are produced with the processing of acrylic resin. Acrylic resin is a form of synthetic polymer with various desirable properties. Acrylic resins are easily produced from methacrylic or acrylic acid. This a very versatile compound that can be formulated to produce a wide range of adhesives with various properties.

Who is an acrylic adhesive manufacturer?

An acrylic adhesive manufacturer is a leading company whose job is to produce industrial bonding solutions by using acrylic polymers. Acrylic adhesives are manufactured in such a way that they provide their characteristic versatility whenever they are applied in different conditions. An acrylic adhesive manufacturer specializes in product formulation, production, customization, quality control, packaging, and distribution.

Why acrylic adhesives are so popular

Acrylic adhesives are special bonding solutions that are produced from acrylic polymers. These are special adhesives that are known due to the wide range of benefits that they offer. These benefits include:

Bond strength: Customers usually demand for acrylic adhesives due to their amazing bonding strengths. They are used in certain applications where reliable and strong bonds are needed. Then again, acrylic adhesive manufacturers can easily formulate these bonding solutions based on specific application or customer requirements.

Transparency: Acrylic adhesives have desirable transparent properties after curing. This is why many customers desire the bonding solution. Transparent adhesives are used in applications that need viability or aesthetics.

Durability: Acrylic adhesives are in high demand due to their durable and robust properties. They can be applied in environments where they have to work by resisting harsh temperatures. Acrylic adhesives can also be used in conditions where resistance to moisture and temperature is needed.

Fast-curing: Acrylic adhesives are usually fancied in industrial environments where their fast-curing properties are applicable. These bonding solutions are known to cure very quickly usually through the process of chemical reaction or evaporation. This way, they can be applied easily in manufacturing facilities to quickly assemble products.

Packaging of acrylic adhesives

Before they ship and distribute their adhesives to customers, manufacturers have to provide the needed packaging for their bonding solutions. To ensure effective product distribution and shipping, manufacturers ensure that the products are packaged with suitable materials. Due to this demand, they usually provide a wide range of packaging solutions such as:

Custom packaging: Acrylic adhesive manufacturers have a wide range of custom product packaging solutions. They can any type of packaging material which depends on the customer’s or product’s requirements. Due to this, they have a wide range of custom product packaging solutions that help ensure efficient and safe shipping.

Jars and bottles: When it comes to the delivery of acrylic adhesives for retail sales, manufacturers use jars and bottles. This type of packaging is usually suited for small-scale customers and applications. They are ideal for customers who require smaller quantities of acrylic adhesives. The containers are sealed using lids or caps to stop leakages or spillages.

Tubes or cartridges: Acrylic adhesive manufacturers also have packaging solutions for customers who need very small quantities of their bonding solutions. This means that this set of customers can get their acrylic bonding solutions shipped in squeeze tubes or cartridges. Acrylic adhesives are produced and used mainly for small repairs and DIY projects.

Shipping with pails and drums

Acrylic adhesive manufacturers usually prefer to ship light orders of adhesives in pails and drums. These shipping products can usually vary in terms of size. The products can range from several litres to 205 litres (55 gallons) of drums. All pails and drums are sealed properly to prevent spillages and leaks during transit.

Shipping acrylic adhesives with intermediate bulk containers (IBCs)

An acrylic adhesive manufacturer can easily ship their products using totes or IBCs (intermediate bulk containers). With totes or IBCs, they can supply several hundreds gallons of acrylic adhesives to their customers and distributors. Totes and IBCs are usually designed to have in-built pallets to ensure ease of product handling during shipping and distribution.

Distribution of adhesives with bulk tanker trucks

Distribution of adhesives with bulk tanker trucks

For industrial customers with very large demands for acrylic adhesives, they can get their products through bulk tanker trucks. Adhesive manufacturers usually make these bulk shipments available to their industrial customers. To distribute the product(s) effectively, tanker trucks are used. The tanker trucks come with very large storage tanks for transporting significant quantities of acrylic adhesives. When the tanks arrive at the required destination, the adhesive products are then offloaded directly inside the storage tank facility provided by the customer.

The role of acrylic adhesive manufacturers with product packaging and shipping

Acrylic adhesive manufacturers play a central role when it comes to suitable industrial product packaging and shipping solutions. This is because they usually package acrylic adhesives to suit various shipping and logistics solutions. Adhesive solution manufacturers use all types of packaging solutions to ensure that the best industry standards. During product packaging and shipping, they usually make sure that the products are packaged safely and securely. The acrylic adhesive package is done in such a way that it can prevent leakages, damages, and contamination during transportation. In addition, they also provide elaborate product documentation and labeling solutions. This ensures compliance with shipping regulations as well as providing product handling information to customers.

For more about an Acrylic Adhesive Manufacturer just got easier,you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.