Non-Flammable Glue

Non-Flammable Glue

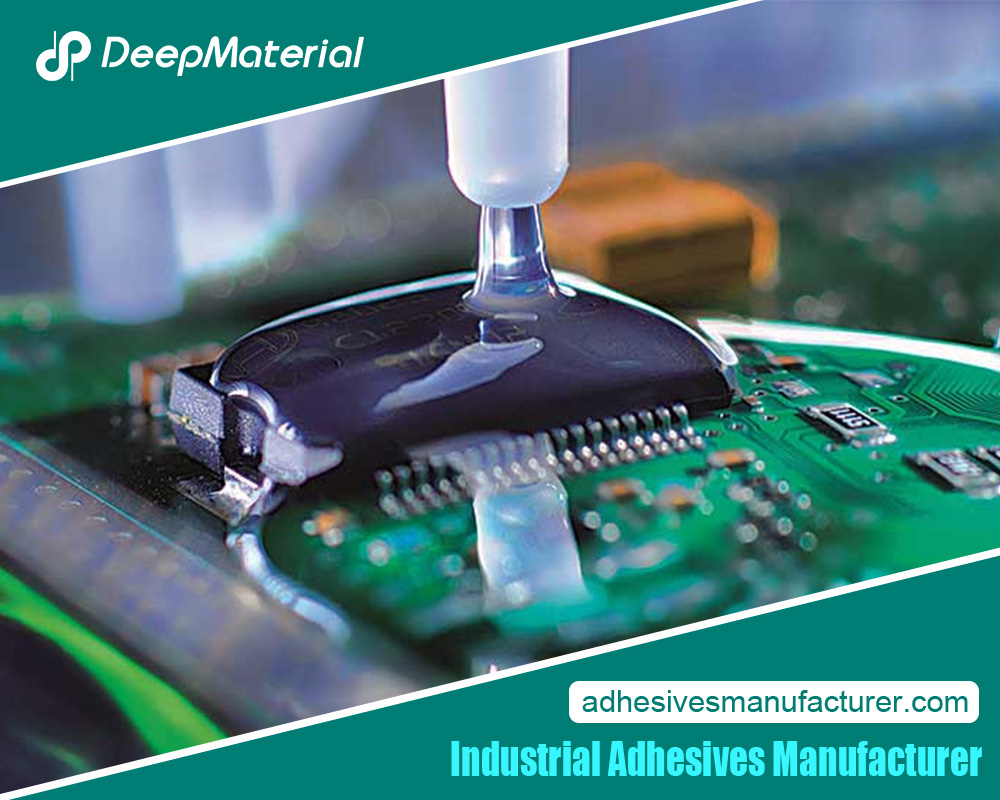

In industries where safety is paramount, the choice of materials can mean the difference between reliability and catastrophe. Non-flammable glue, also known as non-flammable adhesive, is a specialized bonding agent designed to resist ignition and combustion, making it an essential solution in environments exposed to heat, sparks, or open flames. From automotive interiors to aerospace components and industrial manufacturing, these adhesives provide secure bonds without contributing to fire hazards, ensuring both performance and safety.

This article offers an in-depth exploration of non-flammable glue, covering its definition, types, properties, applications (with a strong focus on automotive), challenges, and emerging trends. By understanding its role and evolution, we gain insight into how these advanced adhesives are shaping industries that prioritize fire safety, particularly in the automotive sector, where lightweight materials and electrification heighten the need for non-flammable solutions.

What Is Non-Flammable Glue?

What Is Non-Flammable Glue?

Non-flammable glue refers to adhesives formulated to resist ignition, flame propagation, and combustion, even when exposed to high temperatures or open flames. Unlike standard adhesives, which may contain volatile organic compounds (VOCs) or flammable solvents, non-flammable glues are engineered with fire-retardant additives, water-based formulations, or inherently non-combustible materials. They maintain their bonding strength, structural integrity, and performance across a range of temperatures, making them ideal for safety-critical applications.

Key Characteristics

- Fire Resistance: Does not ignite or sustain flames, often meeting standards like UL 94 V-0 or FMVSS 302 (Federal Motor Vehicle Safety Standard).

- Thermal Stability: Maintains adhesion at elevated temperatures, typically up to 150–300°C (302–572°F), depending on the formulation.

- Chemical Resistance: Withstands exposure to fuels, oils, and solvents.

- Versatility: Bonds diverse substrates, including metals, plastics, composites, and textiles.

- Low Smoke and Toxicity: Produces minimal smoke or toxic fumes when exposed to heat, enhancing safety.

Importance in Industry

Non-flammable glue is critical in industries where fire risks are prevalent, such as automotive, aerospace, electronics, and construction. In the automotive sector, it ensures safety in high-heat zones like engine compartments and battery packs, while supporting lightweight designs that improve fuel efficiency and electric vehicle (EV) range. By reducing fire hazards and meeting stringent safety standards, these adhesives enable innovation without compromising reliability.

Types of Non-Flammable Glue

Non-flammable glues come in various formulations, each tailored to specific applications, substrates, and performance requirements. The main types include:

- Water-Based Adhesives

Water-based non-flammable glues use water as the primary solvent, eliminating flammable VOCs. They are commonly used in automotive interiors for bonding fabrics, foams, and plastics, offering good adhesion and fire resistance up to 150°C (302°F).

- Silicone Adhesives

Silicone-based non-flammable adhesives are flexible and heat-resistant, withstanding temperatures up to 300°C (572°F). They are used for sealing and bonding in automotive engines and EV battery packs, with inherent fire-retardant properties.

- Epoxy Adhesives

Fire-retardant epoxy adhesives, formulated with halogen-free flame retardants, offer high mechanical strength and thermal stability up to 200°C (392°F). They are used in automotive electronics and structural bonding.

- Polyurethane Adhesives

Non-flammable polyurethane adhesives, often water-based or modified with flame retardants, provide strong bonds for composites and plastics. They are used in automotive body panels and interiors, resisting ignition up to 180°C (356°F).

- Inorganic Adhesives

Inorganic adhesives, such as ceramic or silicate-based glues, are inherently non-flammable and can withstand temperatures exceeding 1000°C (1832°F). They are less common in automotive applications but used in exhaust systems or industrial settings.

Materials and Additives

- Base Polymers: Water-based acrylics, silicones, epoxies, or polyurethanes.

- Flame Retardants: Phosphorus, nitrogen, or mineral-based additives (e.g., aluminum hydroxide) to enhance fire resistance.

- Fillers: Silica or alumina to improve thermal stability and strength.

- Curing Agents: Catalysts or heat to initiate bonding.

Properties of Non-Flammable Glue

The performance of non-flammable glue depends on several key properties:

- Fire Resistance

Adhesives must meet fire safety standards, such as UL 94 V-0 (no flame propagation) or FMVSS 302 (low burn rate for automotive interiors). Flame retardants or non-combustible bases ensure compliance.

- Thermal Stability

Maintaining adhesion and structural integrity at elevated temperatures is critical, especially in automotive applications near engines or batteries.

- Mechanical Strength

Adhesives must withstand shear, tensile, and peel forces, ensuring durable bonds under vibration and thermal cycling.

- Chemical Resistance

Resistance to fuels, oils, coolants, and cleaning agents ensures longevity in automotive environments.

- Low Smoke and Toxicity

In a fire, non-flammable glues produce minimal smoke and non-toxic fumes, critical for passenger safety in vehicles or confined spaces.

- Application Ease

Adhesives should be easy to apply via dispensing, spraying, or film, with curing processes (room temperature, heat, or UV) compatible with manufacturing.

Applications in the Automotive Industry

Non-flammable glue is critical in automotive applications, where fire safety is a priority due to high-heat zones, flammable materials, and stringent regulations.

- Interior Components

Automotive interiors use lightweight materials like foams, fabrics, and plastics, which can be fire hazards:

- Headliners and Carpets: Water-based adhesives bond fabrics, meeting FMVSS 302 for low flammability.

- Dashboard and Door Panels: Polyurethane adhesives secure plastic and composite components, resisting ignition.

- Engine Compartment

Engines generate heat and exposure to flammable fluids:

- Gasket Sealing: Silicone adhesives seal oil pans and valve covers, resisting heat up to 300°C and preventing fire risks.

- Sensor Bonding: Epoxy adhesives secure sensors, with flame-retardant properties for safety.

- Electric Vehicles (EVs)

EVs introduce unique fire risks due to battery packs and high-voltage systems:

- Battery Packs: Silicone adhesives seal and bond cells, preventing thermal runaway and resisting ignition.

- Power Electronics: Epoxy adhesives secure inverters and converters, with non-flammable formulations for safety.

- Charging Ports: Polyurethane adhesives bond components, resisting heat from rapid charging.

Exterior and Structural Bonding

Non-flammable adhesives enable lightweight designs:

- Body Panels: Polyurethane adhesives bond composites and aluminum, reducing weight while meeting fire safety standards.

- Heat Shields: Silicone or inorganic adhesives secure heat shields, resisting high temperatures near exhaust systems.

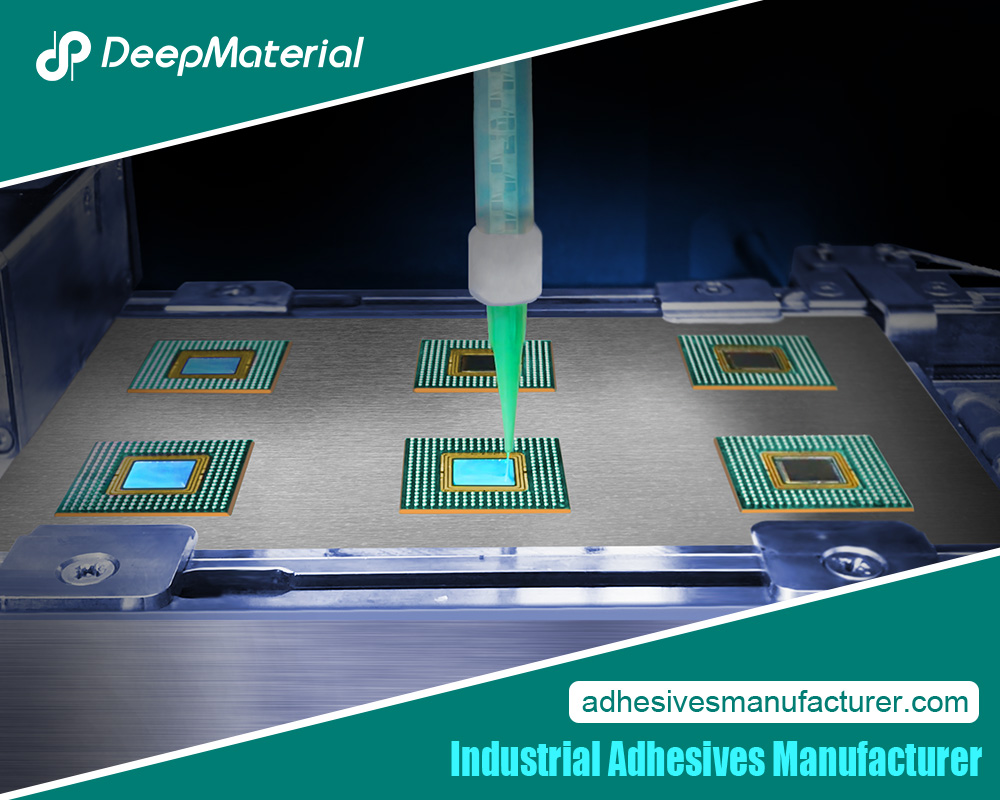

Electronics and Infotainment

Automotive electronics require fire-safe adhesives:

- ECUs and Sensors: Epoxy adhesives bond circuit boards, with flame-retardant properties to prevent fires.

- Displays: Water-based adhesives secure infotainment screens, meeting interior flammability standards.

Specific Examples

- Tesla Model 3: Uses non-flammable silicone adhesives in battery packs to enhance fire safety.

- Volkswagen ID.4: Employs water-based adhesives in interiors, complying with FMVSS 302.

- Formula E: Non-flammable epoxy adhesives bond electronics, ensuring safety in high-performance EVs.

Design Considerations

Developing non-flammable glue for automotive use involves addressing several critical factors:

- Fire Safety Compliance

Adhesives must meet standards like UL 94, FMVSS 302, or ISO 3795, ensuring no flame propagation or low burn rates.

- Temperature Range

Adhesives must maintain performance at operating temperatures, from moderate (interior applications) to high (engine or battery zones).

- Substrate Compatibility

Adhesives must bond diverse materials with varying thermal expansion coefficients, preventing bond failure under heat or vibration.

- Application Method

Ease of application—via dispensing, spraying, or film—impacts manufacturing efficiency. Cure time and conditions must align with assembly processes.

- Environmental Resistance

Adhesives must resist:

- Chemicals: Fuels, oils, and coolants.

- Moisture: Rain or humidity in exterior applications.

- UV Exposure: For adhesives in visible areas.

- Testing and Validation

Adhesives undergo rigorous testing:

- Flammability Tests: To verify compliance with fire safety standards.

- Thermal Cycling: To simulate temperature fluctuations.

- Chemical Exposure Tests: To ensure resistance to automotive fluids.

Challenges in Non-Flammable Glue Development

Developing non-flammable glue presents several challenges:

- Balancing Fire Resistance and Performance

Flame retardants can reduce adhesive strength or flexibility. Formulating adhesives that meet fire safety standards without compromising bonding is critical.

- Cost Pressures

Non-flammable adhesives, especially silicones and epoxies, are more expensive than standard glues. Automakers demand cost-effective solutions, requiring optimized formulations.

- Environmental Impact

Some flame retardants (e.g., halogen-based) are toxic or non-recyclable, conflicting with sustainability goals. Developing eco-friendly alternatives is a priority.

- Processing Complexity

Water-based adhesives may require longer drying times, while heat-cured adhesives complicate manufacturing. Streamlined processes are needed for efficiency.

- Long-Term Durability

Adhesives must maintain fire resistance and bonding strength over a vehicle’s lifespan (10–15 years), resisting thermal aging and environmental degradation.

- Solutions and Innovations

- Halogen-Free Retardants: Phosphorus or nitrogen-based additives improve safety and sustainability.

- Nanotechnology: Nanoparticles enhance fire resistance and strength.

- Hybrid Formulations: Combine water-based and silicone properties for versatility.

- Low-VOC Formulations: Reduce emissions during application.

Future Trends

The future of non-flammable glue is shaped by automotive and industrial advancements:

- Electrification

EVs demand fire-safe adhesives for battery packs, motors, and electronics, with higher thermal stability to prevent thermal runaway.

- Autonomous Vehicles

Self-driving cars rely on electronics in high-heat zones. Non-flammable adhesives will support sensor and ECU reliability, meeting strict safety standards.

- Lightweight Materials

The shift to composites and plastics increases adhesive use, with non-flammable formulations ensuring fire safety in lightweight designs.

- Sustainable Adhesives

Bio-based, recyclable, and low-VOC adhesives will align with automotive sustainability goals, reducing environmental impact.

- Smart Adhesives

Adhesives with embedded sensors could monitor bond integrity or fire risk, enabling predictive maintenance in safety-critical applications.

- Advanced Fire Testing

New standards for EV fire safety will drive innovation in adhesives with ultra-low flammability and smoke production.

- Case Studies and Real-World Impact

- Rivian R1T: Uses non-flammable silicone adhesives in battery packs, enhancing fire safety in rugged EVs.

- BMW 7 Series: Employs water-based adhesives in interiors, meeting FMVSS 302 and reducing VOC emissions.

- Aerospace Cross-Over: Automotive manufacturers adopt aerospace-grade non-flammable epoxies for electronics, improving safety.

Conclusion

Conclusion

Non-flammable glue is a critical enabler of safety and performance in the automotive industry and beyond. From bonding interior fabrics to sealing EV battery packs, these adhesives ensure reliable performance without contributing to fire hazards. Designing them requires balancing fire resistance, mechanical strength, and cost while addressing challenges like environmental impact and processing complexity. As vehicles embrace electrification, autonomy, and sustainability, non-flammable glues will evolve, incorporating eco-friendly materials, smarter features, and enhanced fire safety.

Next time you drive a car or charge an EV, consider the non-flammable adhesives working silently to keep components secure and safe. They’re small in scale, but their impact on the future of mobility is immense.

For more about non-flammable glue, you can pay a visit to Deepmaterial at https://www.adhesivesmanufacturer.com/ for more info.